When it comes to spray painting surfaces, two major techniques dominate the industry: electrostatic painting and conventional spray painting. Both have their strengths, but which one is right for your needs? In this post, we compare the two processes to help you make an informed decision for your next project.

Electrostatic painting works by charging paint particles and attracting them to a grounded surface. This magnetic effect allows for superior coverage, with transfer efficiency reaching up to 95–97%. That means very little overspray, reduced waste, and maximum use of materials.

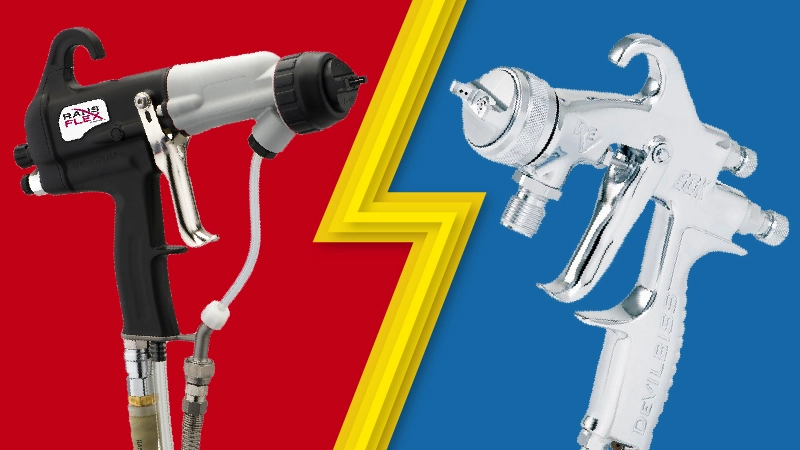

Conventional spray painting, using HVLP or airless systems, typically has lower efficiency. While HVLP systems do reduce overspray compared to older methods, they still don’t match the precision and wrap-around coverage of electrostatic spraying.

Electrostatic painting delivers an even, uniform coat. The charged particles wrap around the object, ensuring all sides are covered smoothly—even in hard-to-reach areas. This results in a sleek, professional finish with fewer imperfections.

Conventional spraying can produce great results too, but it requires more operator skill, especially on surfaces with sharp angles or curves. The finish may be less consistent and more prone to runs or uneven texture.

One of the key advantages of electrostatic systems—especially powder coating—is the low environmental impact. These systems often use solvent-free coatings and generate minimal VOC emissions. Overspray can even be reclaimed and reused, reducing waste significantly.

Conventional spray painting often involves solvent-based paints, which release more VOCs and require more safety precautions. Ventilation and air filtering become especially important in enclosed workspaces.

Electrostatic equipment, including spray guns, control systems, and ovens (in the case of powder coating), involves a higher initial investment. However, the savings on paint and labour over time can make it cost-effective in the long run.

Conventional spray setups are cheaper to start with but tend to use more paint and generate more waste—leading to higher operating costs over time.

Conventional spraying works well on almost any surface and doesn’t require conductivity, making it more versatile—especially for one-off or small jobs.

| Feature | Electrostatic Painting | Conventional Painting |

| Transfer Efficiency | Very high (95–97%) | Moderate (lower with airless) |

| Finish Quality | Smooth and even | Good but less consistent |

| Suitable Materials | Metal or primed conductive surfaces | Wood, plastic, metal, etc. |

| VOC Emissions | Very low (especially powder coating) | Higher (solvent-based paints) |

| Equipment Cost | High | Low |

| Best For | High-end, durable, professional coatings | Versatile, small-scale, general use |

At J&D Sprayers & Makeovers, we use both electrostatic and conventional spray painting methods, depending on the project’s needs. For metalwork, commercial fixtures, or high-durability surfaces, electrostatic painting is often the best solution. For furniture, woodwork, or mixed-material jobs, conventional spraying offers more flexibility.

Need advice on the best method for your specific project? Get in touch with us – we’re here to help you choose the right technique for a flawless, long-lasting finish.